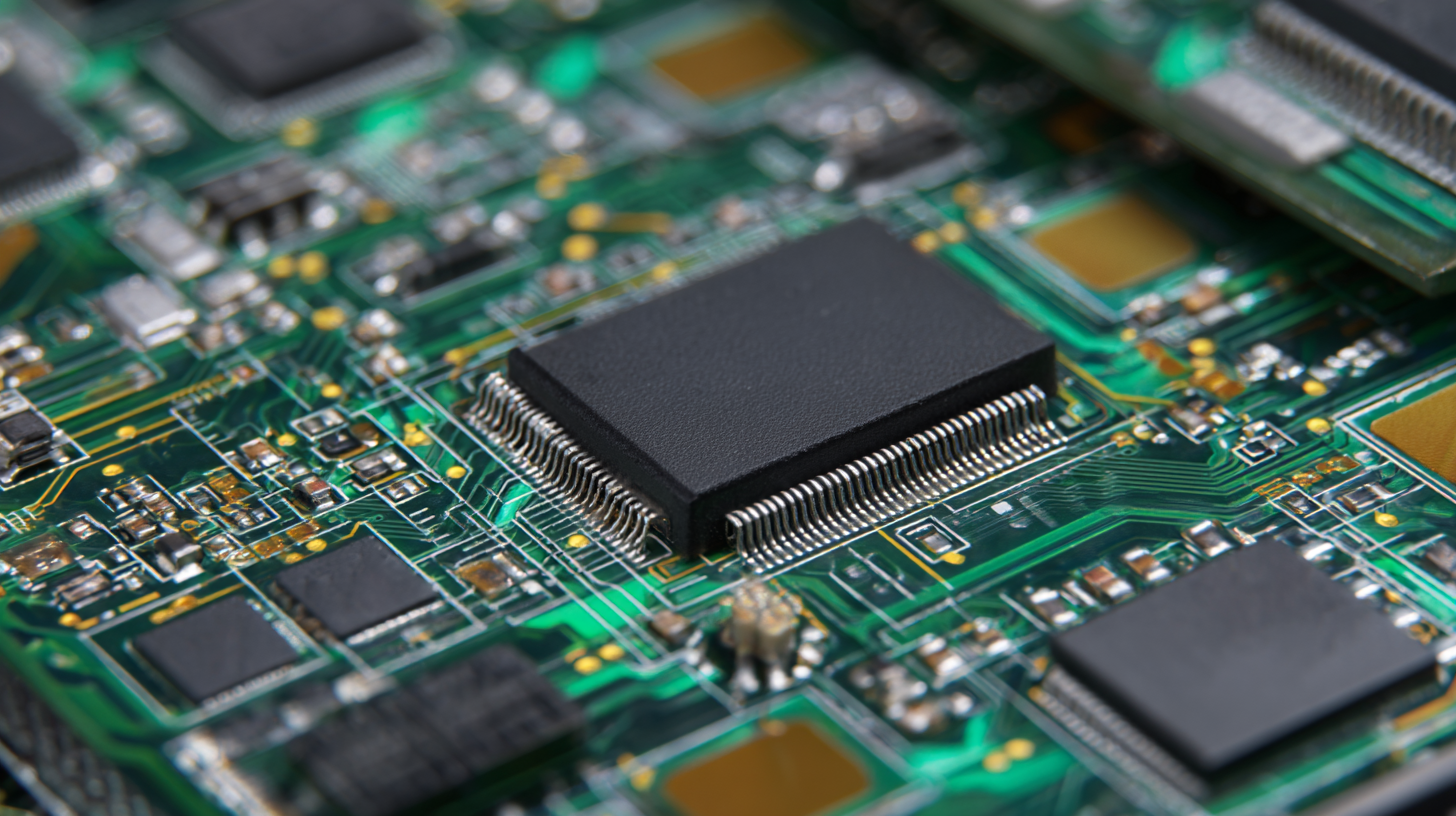

In the ever-evolving world of electronics, the significance of high-quality Printed Boards cannot be overstated. As global buyers seek to harness innovation and efficiency in their projects, understanding the best examples of Printed Boards available in the market is crucial. This tutorial will guide you through the top selections that resonate with various needs and applications, ensuring that you are well-informed about the latest advancements and offerings.

In the ever-evolving world of electronics, the significance of high-quality Printed Boards cannot be overstated. As global buyers seek to harness innovation and efficiency in their projects, understanding the best examples of Printed Boards available in the market is crucial. This tutorial will guide you through the top selections that resonate with various needs and applications, ensuring that you are well-informed about the latest advancements and offerings.

From eco-friendly options to high-density interconnections, the landscape of Printed Boards is diverse and dynamic. Join us as we explore the features, benefits, and standout examples that can elevate your electronic designs and meet the demands of an increasingly competitive industry.

The printed circuit board (PCB) industry is undergoing significant transformation, driven by technological advancements and changing market demands. According to a report by Research and Markets, the global PCB market is projected to reach $100 billion by 2025, growing at a CAGR of 3.7%. This growth is largely fueled by innovations such as advanced materials, miniaturization of components, and increased automation in manufacturing processes. Global buyers must stay abreast of these trends to remain competitive and ensure they source high-quality products that meet evolving technological standards.

One of the key trends reshaping the PCB manufacturing landscape is the rise of flexible and rigid-flex circuit boards. These types of PCBs are gaining traction due to their ability to offer lightweight, compact designs suitable for modern electronics, particularly in the burgeoning IoT and wearable technology sectors. Furthermore, a report from IPC indicates that sustainability is becoming a priority, with manufacturers increasingly adopting eco-friendly practices and materials. This shift not only caters to consumer demand for greener products but also aligns with regulatory requirements that are becoming more stringent globally. Buyers must consider these aspects when selecting manufacturers to ensure compliance and market relevance.

The PCB (Printed Circuit Board) industry is witnessing remarkable production and revenue growth, driven by technological advancements and increasing demand across various sectors. Key metrics such as production volume, revenue per unit, and market share provide valuable insights into the industry's dynamics. In recent years, automated manufacturing processes have significantly enhanced production efficiency, enabling manufacturers to meet the relentless demand for high-quality PCBs in consumer electronics, automotive, and telecommunications.

Moreover, the global shift toward smart devices and IoT has further propelled market expansion. As companies invest in R&D and adopt innovative technologies, the revenue growth in the PCB sector has been substantial. Analysts project that regions like Asia-Pacific will continue to dominate the market, driven by a robust infrastructure of electronics manufacturing and a skilled workforce. Thus, businesses looking to invest or expand in the PCB market must closely monitor these key metrics to navigate challenges and seize new opportunities effectively.

In the world of printed circuit boards (PCBs), quality assurance is paramount for manufacturers aiming to meet the rigorous demands of global buyers. Understanding the various standards and certifications in PCB manufacturing helps ensure that products not only perform reliably but also adhere to safety regulations. Industry standards such as ISO 9001, IPC-A-600, and IPC-A-610 provide a framework for quality management and acceptability of electronic assemblies. These certifications reassure buyers that manufacturers prioritize quality at every stage of production, from design to final inspection.

Moreover, compliance with international certifications such as RoHS and UL can significantly enhance a manufacturer’s credibility. RoHS (Restriction of Hazardous Substances) compliance indicates that the PCB does not contain dangerous materials, appealing to environmentally conscious clients. UL certification signifies that the printed boards have been tested for electrical safety, which is crucial for devices used in various applications, from consumer electronics to industrial equipment. Overall, a clear understanding of these standards and certifications not only aids manufacturers in improving their processes but also serves as a vital checklist for buyers seeking dependable products.

The landscape of printed circuit board (PCB) production has evolved significantly, thanks to advanced technologies that enhance efficiency and precision. Automation plays a crucial role, allowing manufacturers to streamline processes such as drilling, etching, and soldering. Robotic arms and automated assembly lines minimize human error and reduce production time, enabling companies to meet the growing global demand for high-quality PCBs. Additionally, technologies like computer numerical control (CNC) machining have transformed the way PCBs are fabricated, offering unparalleled accuracy and consistency.

Furthermore, the integration of Internet of Things (IoT) devices into PCB manufacturing processes provides real-time monitoring and data analytics. This not only helps in identifying inefficiencies but also allows for predictive maintenance, significantly lowering downtime.

Advanced simulation software enhances design capabilities, ensuring that PCBs can be tested virtually before actual production. As a result, these technologies not only improve production efficiency but also pave the way for innovation and unprecedented customization in PCB designs, catering to the diverse needs of global buyers.

The printed circuit board (PCB) industry is poised for significant growth, with an improved outlook anticipated between 2025 and 2027. This surge can be attributed to increased investments and advancements in technology, underscoring the importance of quality in production. As manufacturers strive to balance quality and cost, Chinese PCB manufacturers are emerging as key players in the global market landscape. The push for value and efficiency has placed a spotlight on comparative analyses of these manufacturers, revealing the delicate balance between competitive pricing and superior quality that global buyers seek.

To capitalize on the evolving market dynamics, stakeholders should focus on a few essential tips. Firstly, investing in sustainable smart manufacturing processes will enhance operational efficiencies and reduce waste, thereby promoting long-term profitability. Secondly, building strong relationships with reliable suppliers is critical; diversification in supply chains can help mitigate risks associated with geopolitical tensions. Lastly, staying informed about industry trends, particularly the forecasted growth of the electronic manufacturing services market from $648.11 billion in 2025 to $1,033.17 billion by 2032, will enable manufacturers to make informed strategic decisions. These strategies will position companies favorably as the demand for high-quality PCB solutions continues to rise globally.