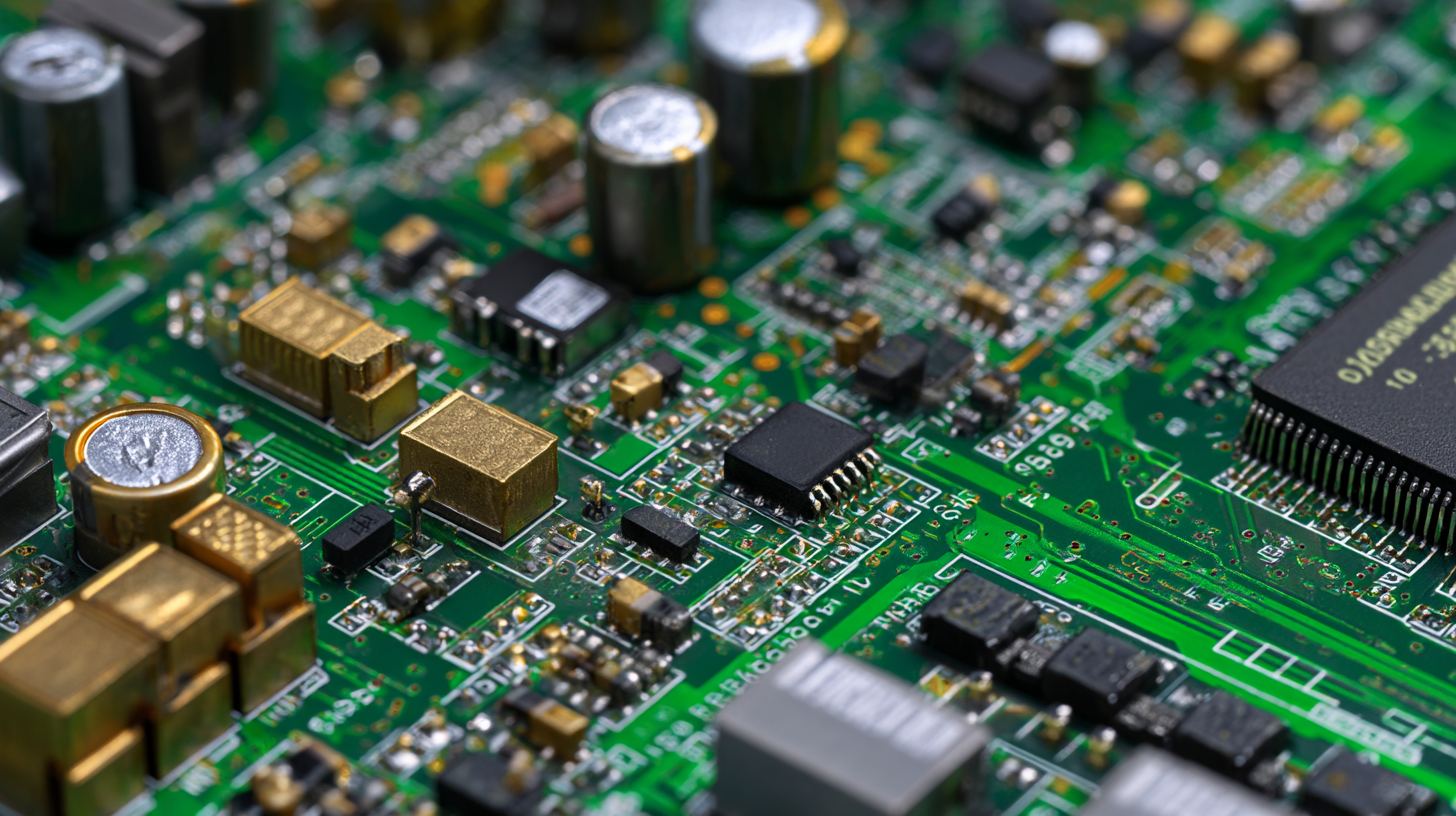

In the rapidly evolving landscape of modern electronics, the significance of a well-crafted Prototype PCB Board cannot be overstated. According to a recent report by MarketsandMarkets, the global PCB market is expected to reach $75.9 billion by 2025, driven largely by the demand for sophisticated electronic devices and the increasing complexity of circuit designs. Prototype PCB Boards play a crucial role in the development process, allowing engineers to test and refine their designs before mass production. This iterative process not only accelerates the product development cycle but also enhances the functionality and reliability of electronic products. As industries increasingly rely on innovation to maintain a competitive edge, understanding the importance of prototype PCB Boards in minimizing errors and expediting time-to-market becomes essential for professionals in the field.

In modern electronics, prototype PCB boards stand as pivotal instruments that accelerate electronic development. A recent industry report highlights that the demand for versatile PCBs has skyrocketed, as they serve a multitude of applications, from consumer gadgets to biomedical devices. The advent of multilayer PCBs, with capabilities of up to 12 layers, is revolutionizing the prototyping landscape, enabling faster iterations and minimization of design errors. Facilities dedicated to this rapid fabrication are essential, as they empower engineers to transition swiftly from concept to prototype, significantly reducing time-to-market.

Furthermore, innovative approaches such as FPGA prototyping are reshaping the way engineers develop Application-Specific Integrated Circuits (ASICs) and System-on-Chip (SoC) solutions. This technique not only expedites the design process but also mitigates risks associated with hardware development. As seen in recent advancements, like the development of range-extended electric vehicles and hybrid-electric aircraft, the integration of cutting-edge technology with efficient PCB prototyping enhances the velocity of engineering projects. The capability to swiftly produce functional prototypes allows for iterative testing and refinement, ultimately driving the entire electronics industry toward faster innovation cycles and enhanced product efficacy.

In modern electronics, the significance of high-quality prototype PCB boards cannot be overstated. These boards serve as the backbone for developing innovative electronic devices, enabling engineers to test and iterate their designs efficiently. According to a recent report by IPC, over 90% of electronic devices rely on printed circuit boards, reflecting their crucial role in today’s technology landscape. When selecting a prototype PCB, focusing on key features such as material quality, layer count, and manufacturing precision becomes essential.

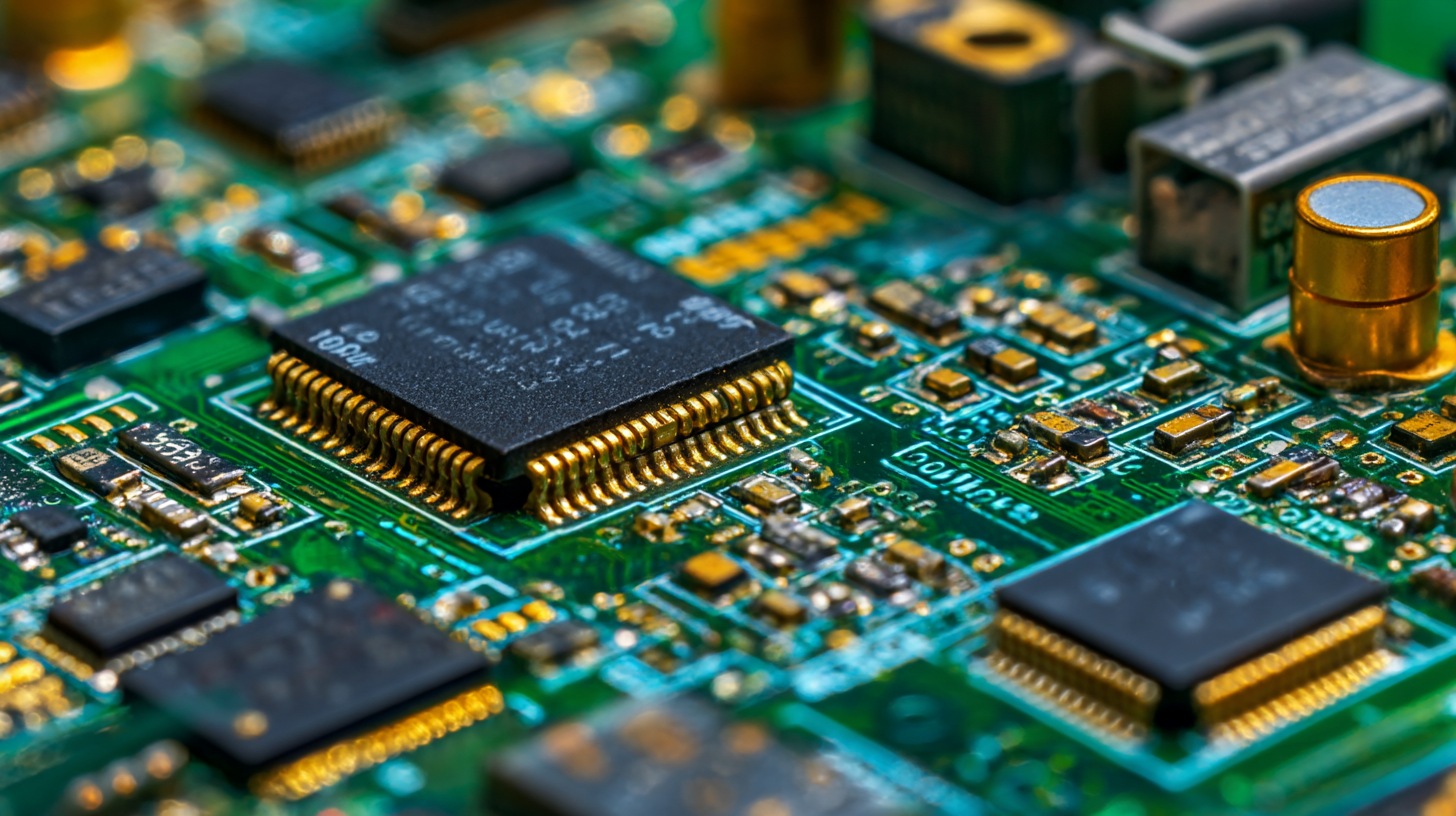

One critical feature is the choice of substrate material, with FR-4 being the most widely used due to its excellent electrical performance and thermal stability. Data from the 2022 Electronics Manufacturing Services (EMS) Industry Report shows that PCBs made with high-grade materials reduce failure rates by approximately 30%. Additionally, the layer count is significant; prototypes with multiple layers allow for more complex circuit designs, enhancing functionality without increasing the board size. Precision in manufacturing processes, such as laser drilling and advanced etching, can greatly impact the performance and reliability of the final product, with studies indicating that tighter tolerances lead to a 15% decrease in assembly defects. These elements are vital for engineers aiming to develop reliable prototypes that can successfully transition into mass production.

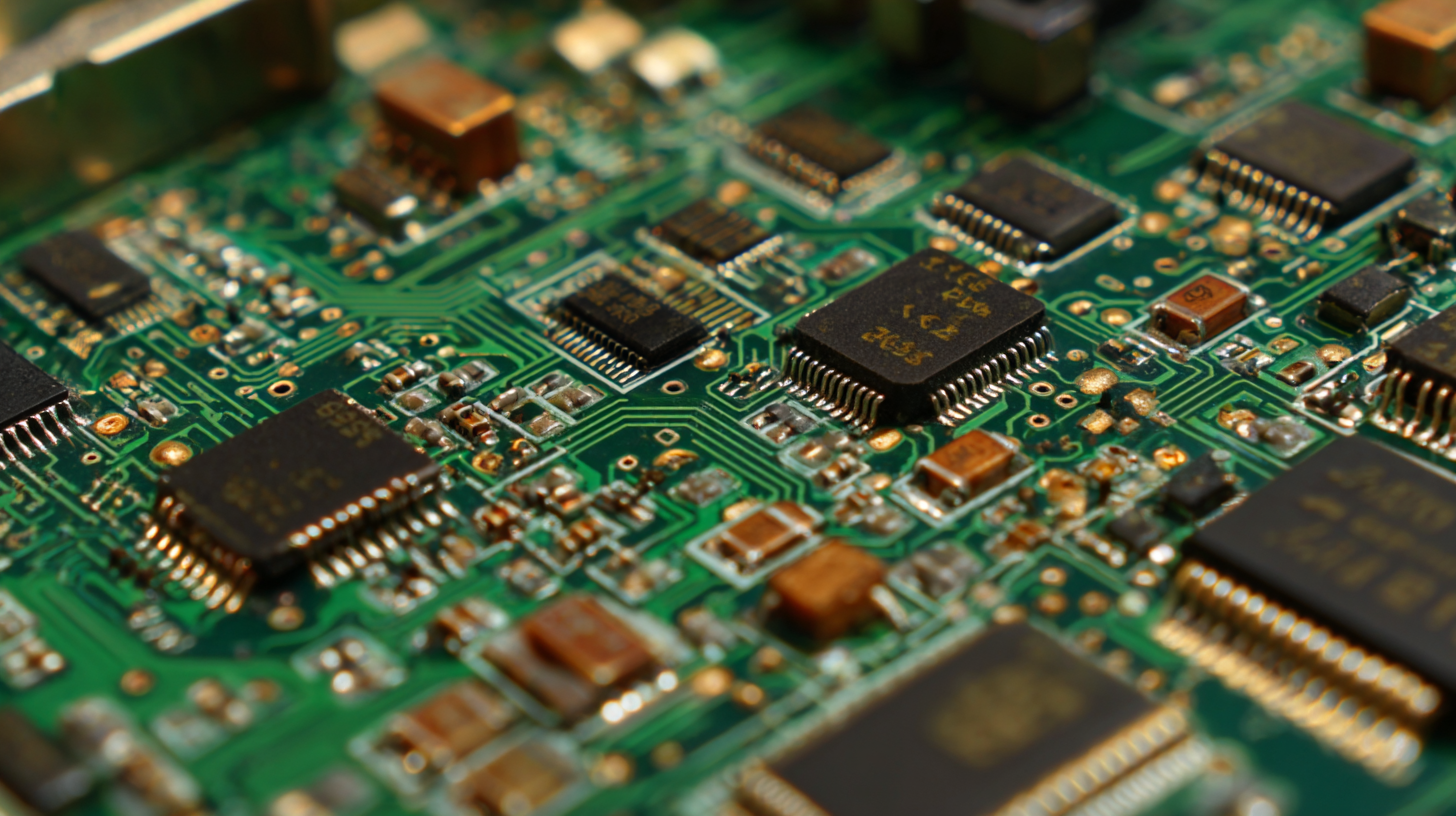

In the fast-paced world of modern electronics, prototyping plays a crucial role in product development. However, the prototyping process often presents significant challenges that can hinder progress. According to a recent report by the IEEE, around 30% of prototyping projects experience delays due to issues such as design flaws and inefficient communication among teams. These hurdles can lead to increased costs and extended time-to-market, making it vital for engineers to identify and address these challenges effectively.

One common obstacle faced during prototyping is the complexity of designing PCB layouts that meet both functional requirements and manufacturing standards. An industry survey conducted by PCB Design Magazine found that nearly 40% of engineers reported that layout issues were the primary reason for redesigns. To mitigate these challenges, employing advanced design software and adhering to robust design guidelines can enhance communication and streamline the prototyping workflow. Furthermore, incorporating iterative testing methodologies can identify potential flaws early in the process, reducing the risk of costly revisions later on. By addressing these common challenges with effective strategies, teams can improve their prototyping success rates and drive innovation in electronics design.

In modern electronics, the design of effective prototype circuit boards (PCBs) is pivotal to the success of a project. One of the best practices in PCB design lies in the seamless integration of electronic computer-aided design (ECAD) and mechanical computer-aided design (MCAD) workflows. Recent advancements have shown that improved collaboration between these disciplines leads to significant reductions in prototype iterations, which in turn enhances accuracy and expedites the development timeline.

Moreover, the introduction of user-friendly tools has further streamlined the PCB design process. The option to access free Gerber files during PCB orders has revolutionized prototypes, granting designers a more cost-effective and efficient pathway to finalize their projects. Additionally, insights from industry trends indicate that leveraging advanced materials and embracing new technologies, such as IoT integration, are becoming essential components of successful PCB design strategies. Reports suggest that incorporating these elements can reduce time-to-market by up to 30%, allowing companies to stay competitive in a fast-evolving electronics landscape.

When it comes to prototype PCB manufacturing, cost-effectiveness is a crucial consideration for many electronics engineers and businesses. Developing a prototype often involves significant expense, but with strategic sourcing, companies can minimize costs without compromising quality. One effective approach is to partner with manufacturers that specialize in low-volume production runs. These suppliers typically offer competitive rates, as they understand the importance of catering to businesses that require flexibility and affordability during the prototyping phase.

Additionally, leveraging online platforms and marketplaces can facilitate connections with multiple PCB manufacturers, allowing designers to compare quotes and timelines efficiently. This competitive landscape often leads to better pricing and service terms. Designers should also inquire about bulk sourcing discounts or negotiation options, especially if future orders are anticipated. By being proactive and resourceful in sourcing, engineers can maintain budget-friendly operations while successfully bringing innovative electronics to market.

| Dimension | Value | Importance |

|---|---|---|

| Material Quality | High-grade FR-4 | Ensures durability and performance |

| Layer Count | 4 Layers | Allows for complex circuit designs |

| Production Time | 7 Days | Quick turnaround for prototypes |

| Testing Services | Functional Testing | Ensures reliability of prototype |

| Cost per Unit | $150 | Cost-effective for initial production |