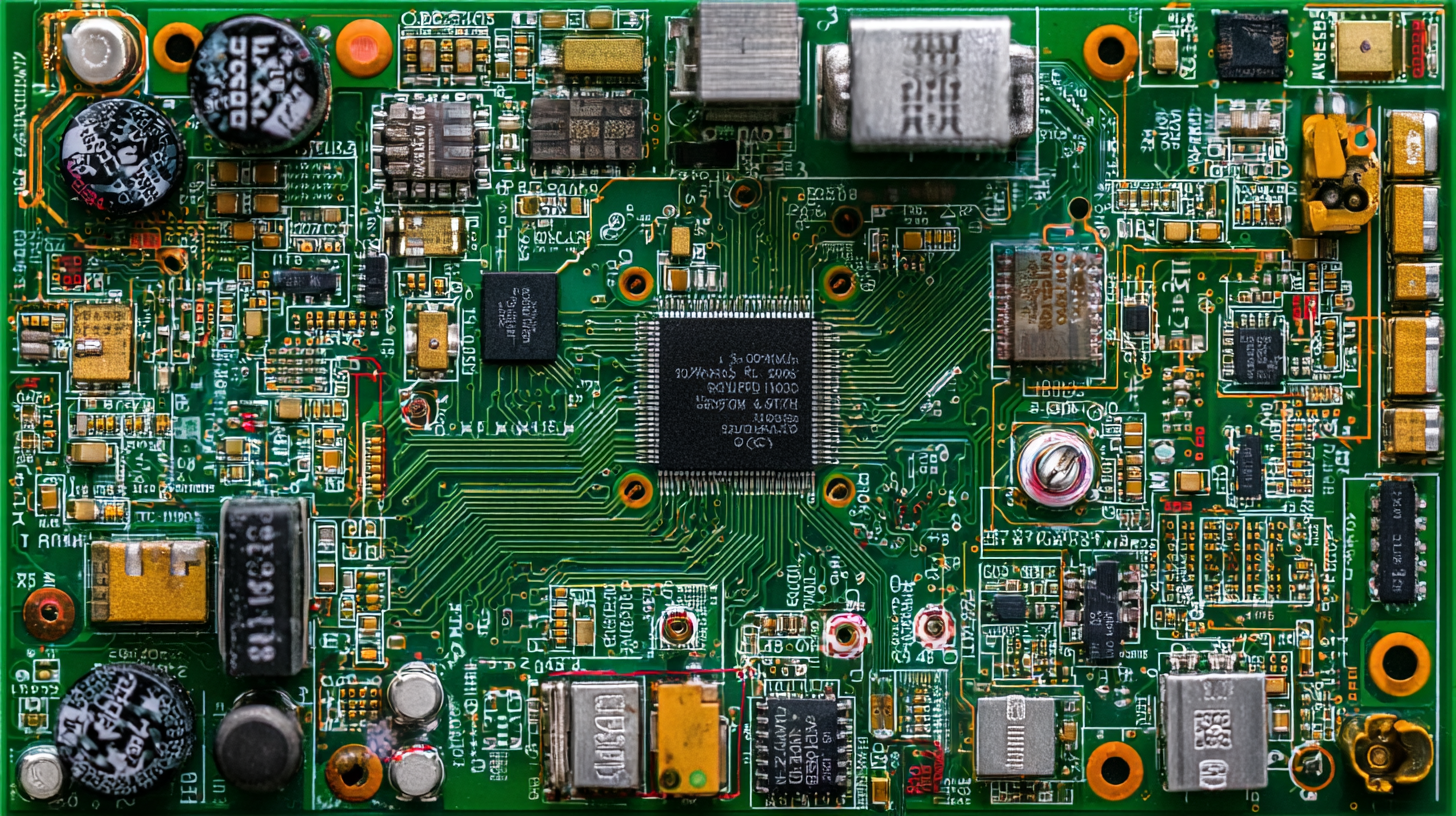

In the ever-evolving world of electronics, the selection of a Print PCB Board is a critical factor that can significantly influence the success of your projects. Whether you are a seasoned engineer or a hobbyist delving into the realm of circuit design, understanding the advantages of choosing the best Print PCB Board tailored to your specific needs is vital. High-quality PCBs not only ensure optimal performance and reliability but also streamline the manufacturing process, reduce costs, and enhance overall project turnaround time.

This blog will explore top strategies for selecting the ideal Print PCB Board, providing insights into material choices, design considerations, and sourcing options. By making informed decisions about your PCB selection, you can elevate your electronic projects and push the boundaries of innovation.

When selecting a quality PCB manufacturer for your electronic projects, several key factors should be considered to ensure efficiency and reliability. First, examine the manufacturer's production capabilities. A good PCB manufacturer should be equipped to handle various types of PCBs, from single-layer to complex multi-layer designs. This versatility can save you time and potential headaches if your project requirements change throughout the development process.

Another significant factor is the quality of materials used in the production process. Ensure that the manufacturer sources high-grade materials that comply with industry standards. This not only affects the performance and longevity of your PCB but also influences the overall reliability of your electronic project.

Tips: Look for certifications such as ISO 9001 or IPC standards, which indicate a commitment to quality. Additionally, consider reaching out to previous clients or checking reviews to gauge satisfaction levels with the manufacturer’s products and services. By taking these steps, you can better navigate the selection process and choose a PCB manufacturer that meets your specific project needs efficiently.

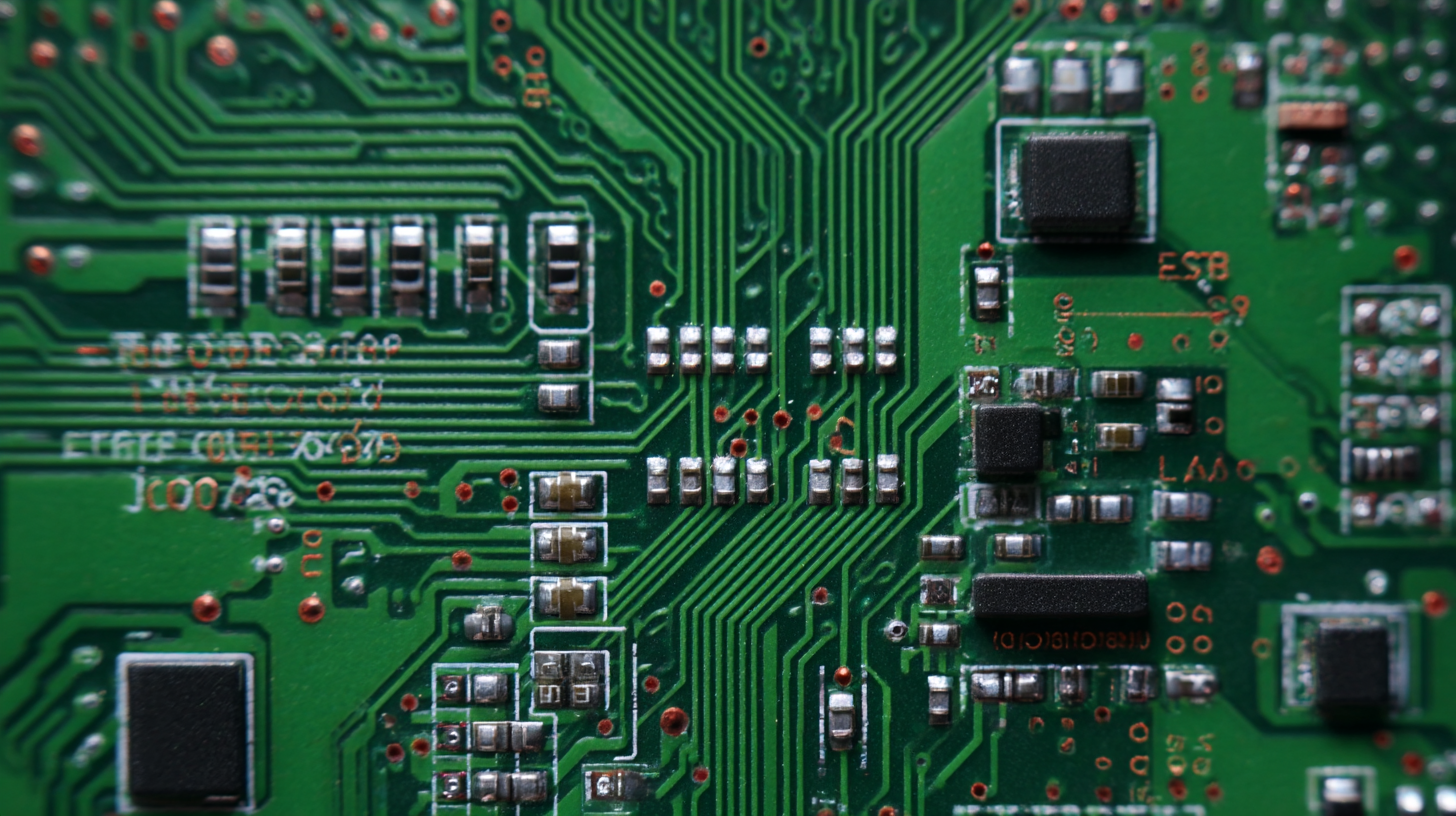

When embarking on electronic projects, the choice of PCB material can significantly influence performance and reliability. Various types of PCB materials are available, each with unique properties suited for different applications. For instance, FR-4, a glass epoxy laminate, is the most commonly used material due to its excellent insulation properties and mechanical strength. Its versatility makes it ideal for a wide range of consumer electronics, from smartphones to automotive applications.

On the other hand, for projects that require higher thermal performance, materials like aluminum or polyimide are advisable. Aluminum PCBs are particularly valued in LED applications where heat dissipation is crucial, while polyimide offers superior flexibility and thermal stability, making it suitable for wearable electronics and high-frequency circuits. Choosing the right material impacts not just the functionality but also the durability of the final product. Understanding the advantages and limitations of each type can empower engineers and hobbyists to make informed decisions tailored to their specific project needs.

| PCB Material Type | Thermal Conductivity | Flexibility | Cost | Applications |

|---|---|---|---|---|

| FR-4 | Good | Rigid | Low | General Purpose |

| CEM-1 | Moderate | Rigid | Very Low | Low-Performance Applications |

| HTS (High-Temperature Super) | Excellent | Rigid | Moderate | High-Temperature Applications |

| Polyimide | Excellent | Flexible | High | Flexible Circuits |

| Aluminum | Very High | Rigid | Higher | LED Lighting |

When embarking on electronic projects, the importance of high-quality printed circuit boards (PCBs) cannot be overstated. High-quality PCBs offer numerous advantages that can significantly enhance the performance and reliability of electronic devices. According to industry reports, the global PCB market is expected to reach $80 billion by 2026, driven by advancements in technology and increasing demand across various sectors, including automotive and consumer electronics. This growth underlines the necessity of investing in superior PCB manufacturing for any serious electronic application.

One of the key benefits of using high-quality PCBs is improved durability and conductive performance. High-grade materials are engineered to withstand heat and mechanical stress, which is especially crucial in applications such as electric vehicles and robotics, where efficiency and longevity are paramount. Moreover, with the rise of artificial intelligence (AI) and machine learning in electronics, circuit boards that can effectively handle increased computational demands are essential. Reports indicate that these state-of-the-art PCBs can significantly reduce the risk of failure during intensive operations, thus ensuring optimal functionality and customer satisfaction. By prioritizing quality in PCB selection, engineers can future-proof their projects against the complexities of modern technology.

When selecting a PCB manufacturer for your electronic projects, evaluating their reputation and customer reviews is paramount. Industry reports indicate that 70% of consumers rely on online feedback before making purchasing decisions, highlighting the importance of transparent reviews for PCB suppliers. Manufacturers with a solid track record often showcase their certifications, adherence to industry standards, and testimonials from satisfied clients. A reputable provider not only assures you of quality but also of reliable customer support, which is essential in troubleshooting any issues that arise during your project.

Tip: Look for manufacturers who have consistently positive reviews on platforms like Reddit, industry forums, or dedicated PCB review sites. Engaging with communities can provide insights into the experiences of others and help you identify trustworthy suppliers.

In addition to reviews, consider the manufacturer's production capacity and lead times. Reports from sources like IPC stress that timely deliveries are crucial for maintaining project schedules. Engaging with manufacturers who communicate proactively about their capabilities can save you unexpected delays.

Tip: Always ask for samples or prototypes before placing large orders to assess the quality and service firsthand. This step can help you avoid costly mistakes down the line and ensure you are making an informed decision.

When selecting the best printed circuit board (PCB) for your electronic projects, striking the right balance between cost and quality is crucial. Many enthusiasts and professionals alike often find themselves at a crossroads, trying to decide whether to invest in more expensive, high-quality options or to save money with cheaper alternatives. While cost-effective choices may seem appealing at first, they can lead to issues such as increased failure rates, poor performance, and heightened maintenance needs down the line.

One significant factor influencing both cost and quality is the manufacturing process. For instance, some manufacturers have begun incorporating advanced laser processing technologies into their workflows. While still viewed as innovative by some, these technologies provide greater precision and efficiency in PCB production. Investing in quality PCBs that employ these modern techniques results in enhanced performance and longevity, ultimately proving to be more economical in the long run. By weighing these aspects carefully, you can find the best fit for your specific project requirements, ensuring both reliability and value without unnecessary compromise.